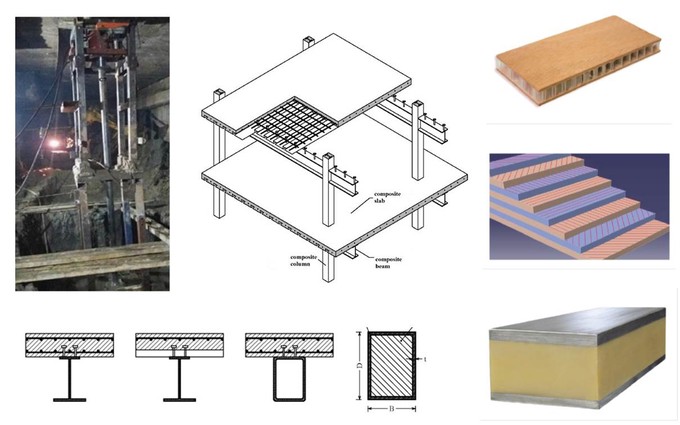

Composite materials (composites) are materials made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. The new material may be preferred for many reasons. Common examples include materials which are stronger, lighter, or less expensive when compared to traditional materials. Typical engineered composite materials include: reinforced concrete and masonry, plywood, reinforced plastics (such as fiber-reinforced polymer or fiberglass), ceramic matrix or metal matrix composites.

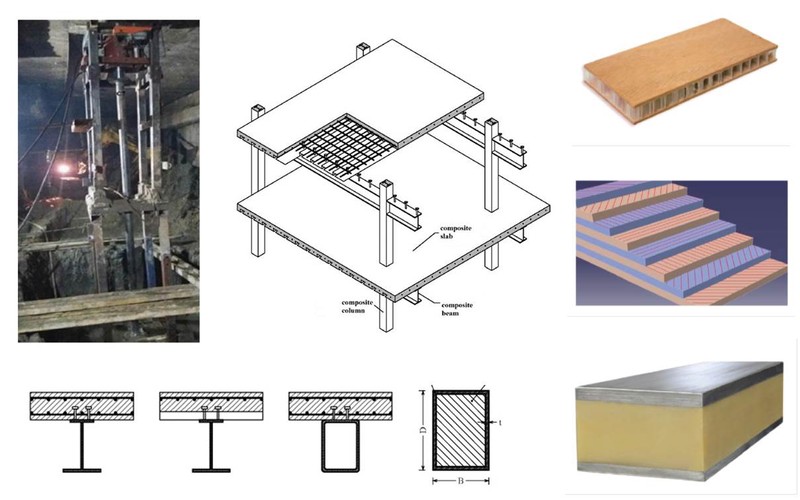

Steel-concrete composite structures imply the use of steel and concrete members joined together into a single item, having a higher level of performance than in the case when the two members act separately. Although very different in nature, concrete and steel complement one another: concrete is efficient in compression and steel in tension; steel components are prone to buckling while concrete can restrain and postpone buckling; concrete gives protection against corrosion and provides thermal insulation, while steel gives ductility to the structure.

The use of composite concrete-filled steel tubes (CFT) for the columns of frame structures is increasing due to advantages they offer over steel or reinforced concrete members: high stiffness and strength, increased ductility, delayed or prevented buckling. These members are modeled numerically either using the 3D solid finite elements in a commercial software or using the frame elements such as a distributed plasticity fiber beam/column elements and with concentrated plasticity beam/column elements.