Innovative system for seismic resistant masonry infills in reinforced concrete frame structures

Abstract

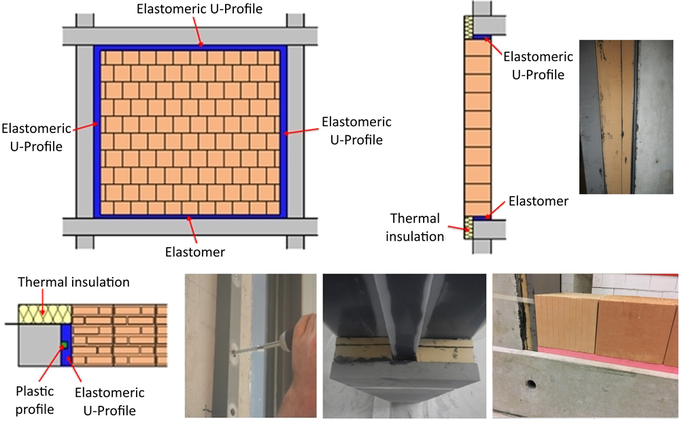

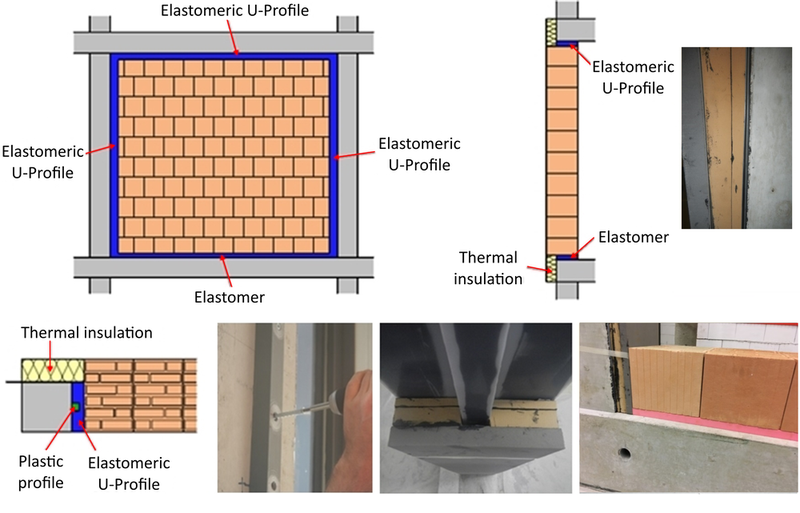

Reinforced concrete (RC) structures with masonry infill walls constitute a significant portion of buildings, since their use is common in many countries due to the good performances of infills with respect to, temperature, noise, moisture, fire and durability. Therefore, RC structures with masonry infill walls are a popular form of construction in seismic regions too. Although, infill walls are mostly considered as non-structural elements and thus are typically neglected in the design process, the observations after earthquakes have shown that they interact with the structural system during seismic actions and that the traditional infill walls, connected with the mortar to the surrounding frame, are vulnerable to earthquake motions. Beside economic loss due to the repair or reconstruction of some infills, repair of damages to structural system, equipment, rental and relocation costs and general income losses, sometimes the consequences were total collapses of buildings and loss of human lives. Therefore, a huge effort has been made to consider the interaction of the structural system with the infill walls, but due to the complexity of the infill wall behaviour, no practical design procedures or solutions have been developed. This thesis presents the INODIS system (Innovative Decoupled Infill System) that makes seismic resistant masonry infills in RC frames structures. This system decouples infill wall form the surrounding frame through a circumferential arrangement of the U-shaped elastomer placed between the infill panel and the frame columns and beams. This allows for relative displacements between the frame and infill, without damaging an infill and simultaneously enabling a support for the out-of-plane loads. The behaviour of the decoupling system is investigated through the tests on system components and on a RC frames filled with hollow clay bricks subjected to separate and combined in-plane and out-of-plane loads. These test results are compared to the results obtained from tests on RC frames with and without traditional infills. The experimental results showed quite brittle behaviour of traditional infills as well as significant reduction of resistances for sequentially applied loading and even higher reductions of the seismic resistance if the loads are applied simultaneously. This was all solved with the application of the INODIS system, which helped in reaching high in-plane drifts without experiencing damage in infill wall and at the same time provided reliable connection for the out-of-plane loading. Additionally, viscoelastic behaviour of elastomers provided high level of energy dissipation and improvеd damping capacity of the infilled frame. The experimental data has been used to validate the numerical micro-model. The developed numerical model describes the inelastic behaviour of the system, as indicated by the obtained results of the overall structural response as well as the formation of damage in the infilled wall. Satisfactory agreement was found between experimental and numerical results. The validated models have been used in parametric studies to identify the significant parameters influencing the behaviour of infilled frames with the INODIS system. The parametric study and experimental findings have been used to develop the design concept for the practical application of the INODIS system. Economic analysis of the solution showed the negligible increase of initial costs, thus it can be concluded that the INODIS systems presents practically applicable solution.